The new High-Tech Upcast Furnace, Drawing, Bunching and Extrusion (printing and band marking) Machines in our greatly enhanced production lines are capable of producing a minimum of 2150 metric tons of copper rod, cable and wire products of various sizes efficiently every month with minimum interference using copper cathode, copper clove, and copper mulberry.

Copper Rod

Copper Wire

Raw Material

Copper Clover

Copper Millberry

Copper Cathode

Wire and Cable

High-quality oxygen free copper conductor wire and cable products have been extensively used by our customers for further downstream such as Home Appliance Wire, Wire harnesses and other applications.

TYPES OF CABLES HAVE BEEN USED IN VARIOUS INDUSTRIES

- Automotive Cables

- LSZHFR & Oil & Gas Cables

- Military Aerospace Cables

- HO7RNF Flexible Cables

- Elevator / Lift Cables

- Fire & Flame Retardant Cables

- Housing & LV Power Cables

- Solar PV & Power Cables

- Instrument Cables

- Welding & Battery Cables

Custom and Specialized Design Cables and Wires

- Rohs and REACH compliance

- Single/Multicore up to max 42 cores

- DIN, JASO, ISO SAE and or SIRIM specifications

- Various PVC, PE, HRFR, Electron Beam Crosslinked TPU, CPE and Engineering Plastic Materials

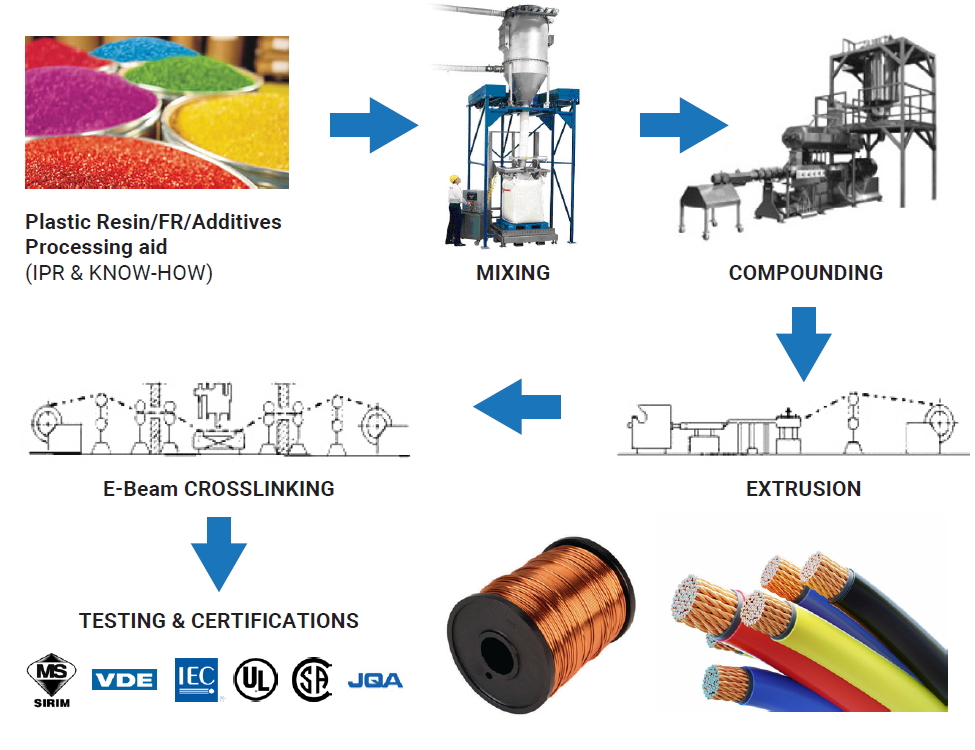

SPECIAL TYPE OF PRODUCT:

Electron Beam cross linking high temperature wires and cables

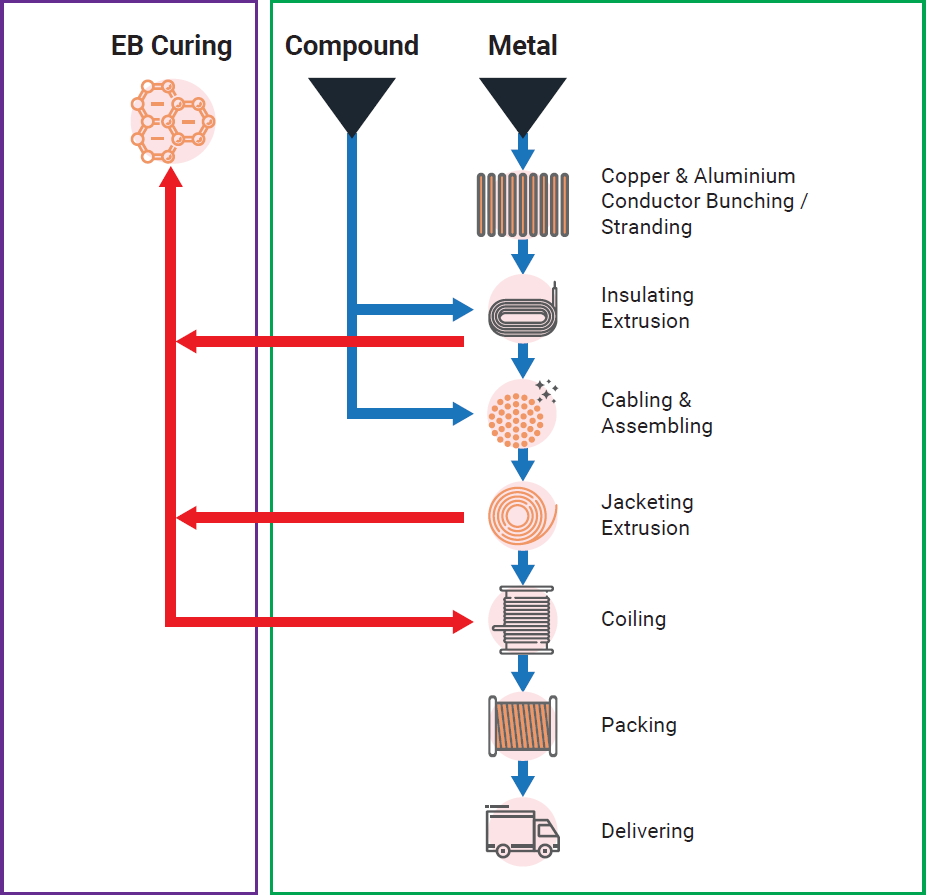

Cable Manufacturing Process

Process Flow

Extrusion Machine

Magnet Wires

Oxygen free copper wire use for magnet wires.

Oxygen free copper wire with wide range of applications such as magnetic coils inside alternators, ballasts, generators, motors and transformers as well as degaussing coil inside television, etc.

Our wires can be drawn into variety of fine & superfine sizes which ensure excellent surface quality and food mechanical strength and elongation.

Welding Wires

Our copper wire is the perfect choice for tin can manufacturers. Despite the existence of aluminium cans, paper packs and plastic bottles; tin cans remain a popular low-cost choice as a container for many food stuffs.

Welding of tin can is a critical step in the can making process to ensure no leakage or contamination of stored food stuff.

With excellent control over tensile strength, elongation, and surface quality, our copper wire is a perfect mould for usage in high speed automated welding lines for today tin can welding.